SMART FACTORY - DIGITAL PACKAGE ↠ 10% Productivity Growth

REAL-TIME DATA COLLECTION based on IoT technology, works on any brand of machines & equipment’s, of any age (15 years old or brand new.

Covering various Manufacturing operations: Textile & Garments, Home Textile, Automotive (Seats, Seat belts, Steering wheels), Furnitures, Shoes, Bags.

CUT TO PACK integration of all equipments: Cutting room, Sewing – Ironing – QA, Printing & Embroidery, Washing, Finishing – Ironing – Packing.

SMART FACTORY – DIGITAL PACKAGE guarantee minimum 10% Productivity growth by creating an eco-system:

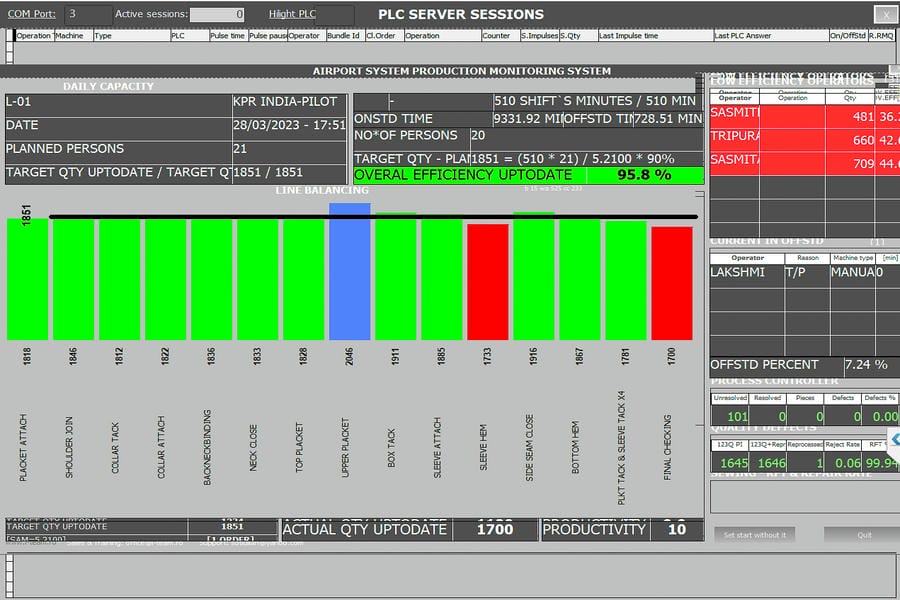

- 1. PMS IoT – PRODUCTION MONITORING SYSTEM – amazing IoT data collection from each machine

- – counting PRODUCED QUANTITY

- – calculate OVERALL EFFICIENCY for operators, line, factory

- – register OFF STANDARD TIME – loss time

- – Dashboard TV display in each line showing Supervisory KPI of the line – LINE BALANCING, PRODUCED QTY, OFF STANDARD TIME, LOW EFFICIENCT OPERATORS, QUALITY KPI

- 2. QA – QUALITY ASSURANCE – complete coverage of the QA system

- – Digital Traffic Light – Rowing QC

- – End Line QC – 2nd defect registration of the reasons (fabrics, accessories, etc)

- – End Line QC – sewing repairs defect registration (once a sewing defect identify, the operator which produced that sewing is getting a warning alarm on his tablet

- – End Line QC – measuring garments using BAGEL – Digital Tape Measuring device

- 3. IE – INDUSTRIAL ENGINEERING – technical tools able to deliver MEDIA content directly in the Shop Floor tablets

- – TECH PACK available on tablet

- – VIDEOS – SEWING BEST PRACTICE – available for DIGITAL TRAINING

- 4. MM – MECHANICAL MAINTENANCE – professional apps to manage all mechanics and spare parts for a factory

- – REAL-TIME maintenance call from operators to mechanics / REAL-TIME status of engaging mechanics

- – Spare parts consumption per machines

- – Maintenance cost per machines

- – Preventive maintenance

- – Mechanics digital training using videos on tablets

- – Optional AR – Augmented Reality – training and troubleshooting

- 5. iHR – INTERACTIVE HUMAN RESOURCE – calculation and display interface to the workers & staff

- – Registration of attendance ACTUAL WORKING TIME – REAL START TIME & END TIME

- – DIRECT INTERACTION between operators and factory management; exchange notifications on tablets

- – REAL-TIME SURVEYS and rating OPERATORS SATISFACTION LEVEL

- – Calculation of BONUS SYSTEM or PIECE RATE SYSTEM è transparency

- – CHAMPIONSHIP CHALLENGES where operators from same operation are challenged to compete each other

- 1. PMS IoT – PRODUCTION MONITORING SYSTEM – amazing IoT data collection from each machine

ANDROID TABS INTERFACE, user friendly, background changing colours based on Overall Efficiency for a quick Operator visual understanding of their performance, quality defects displayed on Tabs, salary & bonus calculation available directly to Operators.

Once you start using it … you cannot get enough of it !

DIGITIZE YOUR MANUFACTURING, EMBRACE SMART FACTORY & IoT TECHNOLOGY

Benefits

DIGITIZE your operation CUT TO PACK

Guaranteed increasing Productivity of 10%

Complete package Production - Quality - Maintenance - IE - HR

REAL TIME collecting data's - managers take decisions

Questions & Answers

What services does your business provide?

Our services varies depending on the specific Factory Layout characteristics, complexity and size of the project you require. We offer customized solutions to fit each client's unique needs and budget. Please contact us.

How much do your services cost?

Each project will be discussed and priced according with the services and complexity of the project. Please BOOK NOW the Consultant for a first meeting.

How do I get started with your services?

BOOK A MEETING with the Consultant and share with him the details of the project. Consultant will evaluate the project and make an offer. BOOK A MEETING with Consultant

How much time will take your services?

Depending on the project complexity, duration is anywhere between 2 weeks to 2 months Please contact us.

What happens next ?

After you receive the Factory layouts you can use in a Feasibility Study to get a funding, or deliver it to Structural Engineers to execute the Architectural Design of the building using the Factory Layouts deliver by our Consultants.

What services do i get ?

Project consist of software, hardwares, training & implementation. Optional we can offer IE consulting services. BOOK NOW a meeting with our Consultant !

How much do your services cost?

BOOK NOW a meeting with us, will talk and learn technical details of your operation and will make a price tailored to your project complexity.

What are usually the ROI ?

At minimum 10% Productivity growth, we calculate a ROI of 12-16 months, very attractive.

We even reach 15-20% Productivity growth, pls do the math.

BOOK NOW a meeting with our Consultant !

How do I get started with your services?

BOOK NOW a meeting with Consultant, that's all you need to do.