FabricQC

Smart Quality Inspection with AI & Vision Systems

FabriQC specializes in AI-powered vision systems that bring intelligence, speed, and precision to industrial quality inspection.

By replacing manual checks with advanced image processing and machine learning, we help factories detect defects in real time, reduce human error, and ensure consistent product quality.

Beyond inspection, our systems build a rich history of defect data, unlocking valuable insights into product trends, recurring issues, and process inefficiencies over time. This data-driven approach empowers manufacturers to make smarter decisions, improve root-cause analysis, and drive continuous improvement.

Partner with FabriQC to modernize your inspection process, gain long-term visibility into product quality, and deliver excellence at scale.

FabriQC offers a powerful AI-driven solution for automated visual inspection in manufacturing environments. Our system empowers factories to shift from manual, error-prone quality checks to intelligent, real-time defect detection powered by image processing and machine learning.

Compatible with any brand or age of machinery, FabriQC brings efficiency, precision, and traceability to production floors across industries.

Industry-Wide Applicability

FabriQC is built for flexibility across a wide range of fabric types and production environments. Whether you’re working with woven and knitted textiles, denim, nonwovens, technical and industrial fabrics, synthetic performance materials, or natural and synthetic leather, our system adapts to your inspection needs. From soft apparel fabrics to heavy-duty upholstery and coated textiles, FabriQC integrates seamlessly into your production line. It supports quality control from the early fabric stage to the final packed product.

Core Capabilities of FabriQC

1. AI-Powered Visual Inspection

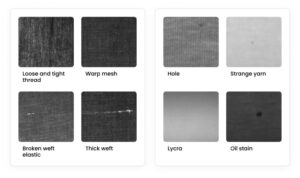

+ Detects surface defects, fabric flaws, oil stains, spots, holes, lines and more

+ Real-time defect detection with high accuracy (90%+)

+ Multi-camera support for complex inspection needs

+ AI model improves continuously based on operator feedback

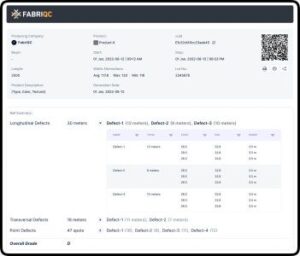

2. Defect Data History & Quality Intelligence

+ Digital record of all defects by category, image, location, and time

+ Historical analytics to identify trends and root causes

+ Supports real-time alerts to prevant more wastes

+ Enables full traceability of products across batches and time

3. Operator Interface & Feedback Loop

+ Tablet-based UI for operator visibilty and performance tracking

+ Instant defect map and defect images

+ Transparency in quality KPIs: rejection rate, speed, defect type

4. Factory-Level Smart Dashboards

+ Real-time visualization of key metrics:

– Defect rates

– Defect sizes

– Defect breakdown by category

+ Compare quality across lines, shifts, or operators

+ Custom alerts for sudden changes or quality drops

+ API integration with MES/ERP systems

Why FabriQC?

FabriQC empowers manufacturers to move beyond reactive quality control and into a new era of proactive, data-driven production. With automated visual inspection, complete defect traceability, and actionable insights.

+ Eliminate subjective visual checks

+ Improve first-pass quality and reduce rework

+ Build trust with clients through traceable quality logs

+ Reduce customer returns and complaints

+ Empower teams with data-driven decision-making

Artificial Intelligence Surface Inspection

Technical support & Training

Smart Defect Detection Device

Smart Factory - Machine Vision Device

2020

Denim fabric defect detection device started

Oman

2022

Lunch the knitted, woven and industrial textiles defect detection device

2023

Lunch the web based defect annotation and AI training platform

2024

Implementation of FabriQC in 5 factories